Capsule filling machines are an essential piece of equipment for pharmaceutical companies, dietary supplement manufacturers, and even those in the herbal and cosmetic industries. These machines automate the process of filling capsules with powders, granules, or liquids, making them efficient, accurate, and cost-effective.

If you're in the market for a capsule filling machine in 2025, understanding the cost structure, the different types of machines available, and the features to look for can help you make an informed decision. In this article, we will explore the different types of capsule filling machines, their costs, and the factors that influence pricing.

Table of Contents

- What is a Capsule Filling Machine?

- Types of Capsule Filling Machines

- Manual Capsule Filling Machines

- Semi-Automatic Capsule Filling Machines

- Fully Automatic Capsule Filling Machines

- Factors That Affect the Cost of Capsule Filling Machines

- Cost of Capsule Filling Machines in 2025

- YITI Capsule Filling Machine - Size 00 (100 Holes)

- YITI Capsule Filling Machine - Size 1 (400 Holes)

- Advantages of Investing in a Capsule Filling Machine

- Frequently Asked Questions (FAQs)

- Conclusion

What is a Capsule Filling Machine?

A capsule filling machine is a piece of equipment used to fill empty capsules with powder, granules, or liquids. These machines are highly valued in the pharmaceutical and nutraceutical industries, as they allow for mass production of capsules in a quick and efficient manner. By automating the capsule filling process, manufacturers can achieve high precision, reduce human error, and meet production demands more effectively.

Capsule filling machines come in various models, from manual machines for small-scale production to fully automated machines for large-scale commercial operations. They differ in terms of speed, efficiency, and ease of use, with prices varying significantly depending on these factors.

Types of Capsule Filling Machines

There are three main types of capsule filling machines available in the market:

Manual Capsule Filling Machines

Manual capsule filling machines are ideal for small-scale operations or for businesses that produce capsules in small batches. These machines are often hand-operated, meaning that the user has to manually insert the powder or other contents into each capsule. While they are slower than automated machines, manual capsule fillers are much more affordable and are a great choice for startups or small businesses.

Features of Manual Capsule Filling Machines:

- Typically used for small-scale production.

- Operated by hand or with minimal mechanical assistance.

- Lower cost compared to automatic machines.

- Can be used for a variety of capsule sizes and types.

Cost Range: $30 - $500 (depending on the number of holes and capacity).

Semi-Automatic Capsule Filling Machines

Semi-automatic capsule filling machines combine manual labor with automated features to speed up the process while maintaining accuracy. These machines are suitable for medium-scale operations and are often used by businesses that need to fill a larger number of capsules but don't require full automation.

Features of Semi-Automatic Capsule Filling Machines:

- Requires some manual input for setup and operation.

- Provides faster filling speeds than manual machines.

- Can handle a larger variety of capsule sizes and types.

- More precise than manual machines, with less risk of human error.

Cost Range: $500 - $5,000 (depending on size and capacity).

Fully Automatic Capsule Filling Machines

Fully automatic capsule filling machines are designed for large-scale production. These machines offer the highest level of automation, allowing for continuous production of capsules with minimal human intervention. They are capable of high speeds and high-volume production, making them ideal for pharmaceutical companies or large nutraceutical manufacturers.

Features of Fully Automatic Capsule Filling Machines:

- Fully automated operation.

- High-speed production, ideal for large-scale businesses.

- Minimal manual input required.

- Capable of filling thousands of capsules per hour.

Cost Range: $10,000 - $100,000+ (depending on production speed, capacity, and additional features).

Factors That Affect the Cost of Capsule Filling Machines

Several factors contribute to the cost of capsule filling machines. These factors range from the complexity of the machine to the features that influence its production capacity and speed.

1. Machine Type

The type of capsule filling machine you choose—manual, semi-automatic, or fully automatic—directly impacts the price. Manual machines are the least expensive, while fully automatic machines come with a hefty price tag due to their advanced features and capabilities.

2. Production Capacity

A machine's capacity is typically measured by the number of capsules it can fill per cycle or per hour. Machines with higher production capacities are generally more expensive. If you need to fill thousands of capsules each day, you’ll need to invest in a machine that can handle large-scale production.

3. Automation Level

Machines with more automation features (such as automatic powder filling, capsule sorting, and sealing) generally cost more. Fully automated machines can operate without human intervention, increasing their price compared to semi-automatic or manual versions.

4. Additional Features

Some capsule filling machines come with specialized features such as easy-to-clean designs, automatic capsule separation, or the ability to fill different types and sizes of capsules. These features can increase the cost, but they can also improve the efficiency and versatility of the machine.

5. Brand and Quality

The reputation of the manufacturer can influence the price. Well-known, high-quality manufacturers typically charge more for their machines due to the durability, performance, and warranty that they offer.

Cost of Capsule Filling Machines in 2025

When considering the price of a capsule filling machine in 2025, it's important to look at specific models that meet your needs. Below are two examples of YITI Capsule Filling Machines and their prices:

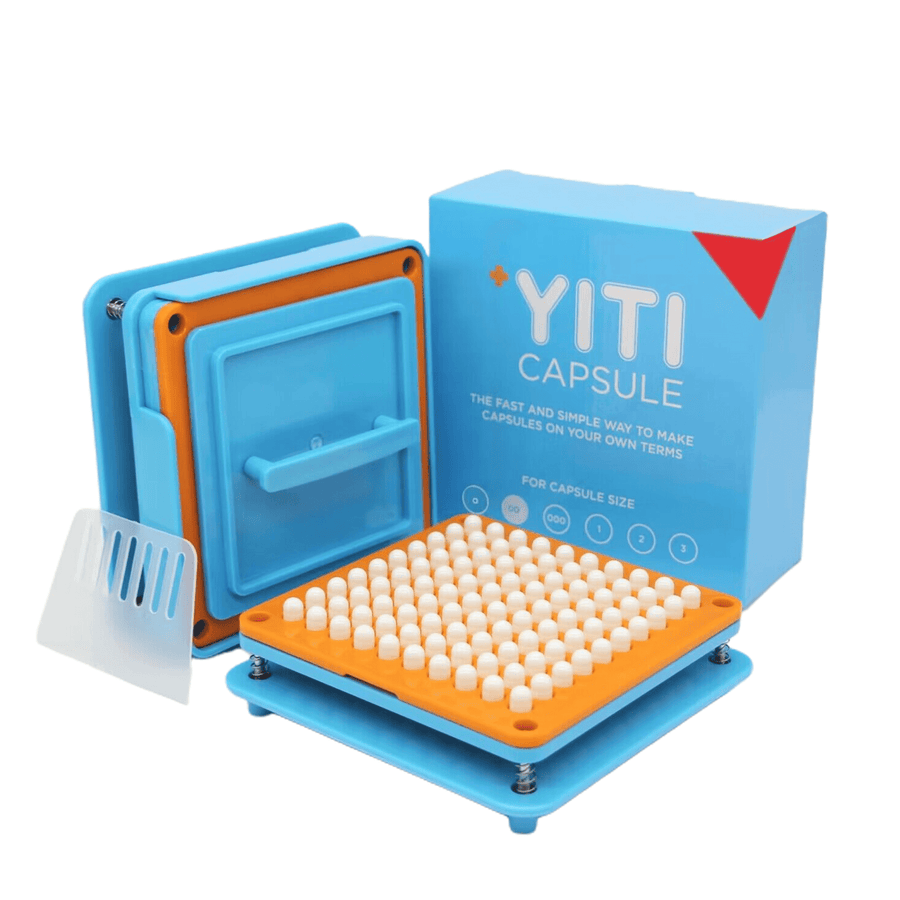

YITI Capsule Filling Machine - size 00 - 100 Holes

Price: $38.95

This manual capsule filling machine is designed for small-scale use and is perfect for businesses that need to fill fewer capsules at a time. It has 100 holes for filling Size 00 capsules, making it a great choice for those just starting out or looking to fill small batches.

Key Features:

- Manual operation.

- Fits Size 00 capsules.

- Simple design for easy operation.

- Compact and portable.

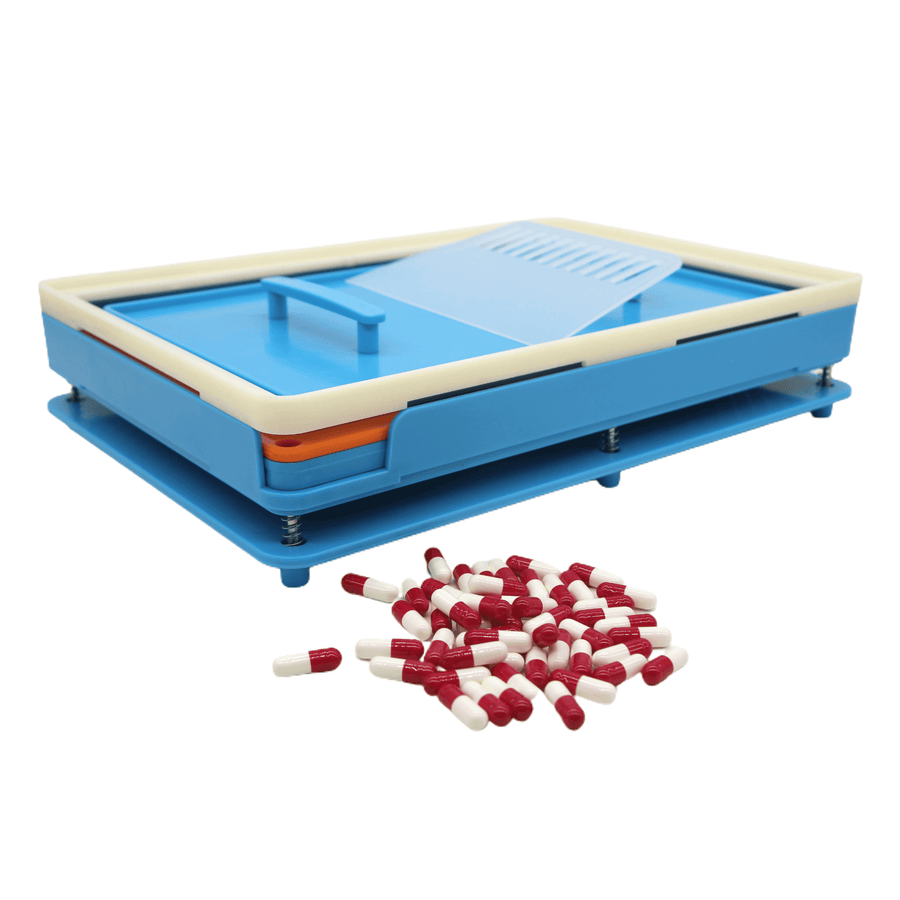

YITI Capsule Filling Machine size 1 - 400 Holes

Price: $149.99

For businesses that need to fill larger batches, this semi-automatic capsule filling machine offers 400 holes, making it more efficient than smaller models. It is ideal for medium-scale production and can handle a larger volume of capsules.

Key Features:

- Semi-automatic operation.

- Fits Size 1 capsules.

- 400 holes for high-speed filling.

- Durable and easy to clean.

Advantages of Investing in a Capsule Filling Machine

Investing in a capsule filling machine can offer several key advantages for your business:

1. Increased Efficiency

Automating the capsule filling process helps increase production speed and reduce human error, resulting in more efficient operations and fewer mistakes.

2. Cost-Effective

While the initial investment may be significant, a filling machine can save money in the long run by reducing labor costs and increasing production capacity.

3. Versatility

Many modern capsule filling machines can handle various types of powders, granules, and liquids, making them versatile enough for a wide range of applications.

4. Consistency and Accuracy

Machines ensure consistent capsule weight and content, improving the quality of your products and meeting regulatory standards.

Frequently Asked Questions (FAQs)

1. What is the difference between manual and automatic capsule filling machines?

Manual machines require human input for filling capsules, while automatic machines perform the entire filling process without the need for operator intervention. Automatic machines are more efficient and suitable for high-volume production.

2. How do I choose the right capsule filling machine for my business?

The right machine depends on the scale of your production. Small businesses or startups may benefit from manual or semi-automatic machines, while larger companies with higher production demands may need fully automated machines.

3. Are capsule filling machines easy to clean?

Yes, many capsule filling machines are designed to be easy to clean, with features like removable parts, smooth surfaces, and user-friendly maintenance procedures.

Conclusion

The cost of capsule filling machines in 2025 varies depending on the type of machine, production capacity, and automation level. If you are starting small, a manual machine like the YITI Capsule Filling Machine (Size 00, 100 Holes) can be a great choice. For medium-scale production, the YITI Capsule Filling Machine (Size 1, 400 Holes) offers excellent efficiency at a competitive price.

Investing in a capsule filling machine can save time, reduce labor costs, and ensure consistent product quality. By understanding the different types of machines and their costs, you can choose the right equipment for your business needs.