Table of Contents

- Introduction

- Overview of Manual Capsule Filling Machines

- Main Parts of a Hand Operated Capsule Filling Machine

- Case Study: YITI 100-Hole Capsule Filling Machine (Size 2)

- How the Components Work Together

- Tips for Effective Use and Maintenance

- Frequently Asked Questions

- Summary Table: Capsule Filler Parts & Functions

Introduction

A hand-operated capsule filling machine is a must-have tool for pharmacists, herbalists, supplement businesses, and DIY health enthusiasts. It simplifies the encapsulation process by allowing users to fill capsules with powders, herbs, or supplements quickly and accurately—without electricity.

Overview of Manual Capsule Filling Machines

Manual capsule fillers, like the YITI 100-hole machine, are designed for small-batch production. These devices enable you to fill empty hard gelatin or vegetable capsules (typically Size 0–4) with powdered substances in a safe, sanitary, and efficient manner. They're ideal for health professionals, supplement brands, and at-home formulators who want precise control over ingredients.

Benefits of Manual Capsule Filling Machines

- Affordable: Cost-effective compared to semi- or fully-automatic models

- Portable: Compact design for easy use at home or in clinics

- Accurate dosing: Ensures consistency within ±3% variance

- Time-saving: Can produce up to 100 capsules in 10–15 minutes

Main Parts of a Hand Operated Capsule Filling Machine

A standard manual capsule filler has 6–9 essential components. Understanding each part’s role is key to operating the machine efficiently and extending its lifespan.

1. Base Plate

- Function: Holds the entire machine structure in place

- Material: ABS or stainless steel (in high-end models)

2. Alignment Plate

- Function: Aligns empty capsules (body + cap) with pre-drilled holes

- Design: Typically has 100 holes aligned with the capsule size

3. Capsule Body Plate (Lower Plate)

- Function: Holds the bottom halves of the capsules during filling

- Compatibility: Each machine is matched to a specific capsule size (e.g., Size 2)

4. Capsule Cap Plate (Upper Plate)

- Function: Holds the top halves (caps) of the capsules for closing

5. Powder Spreader Card / Tamper

- Function: Evenly spreads powder across capsule bodies

- Additional role: Tamper used to compact powder for higher fill volume

6. Middle Plate (Optional)

- Function: Assists in separating capsule tops from bottoms during setup

7. Tamping Tool

- Function: Pushes powder into capsules to maximize fill level

- Design: Can be a manual rod or integrated within the spreader

8. Locking Plate

- Function: Applies pressure to lock capsule tops and bottoms together

9. Ejector Plate

- Function: Releases the filled capsules once sealed

Case Study: YITI 100-Hole Capsule Filling Machine (Size 2)

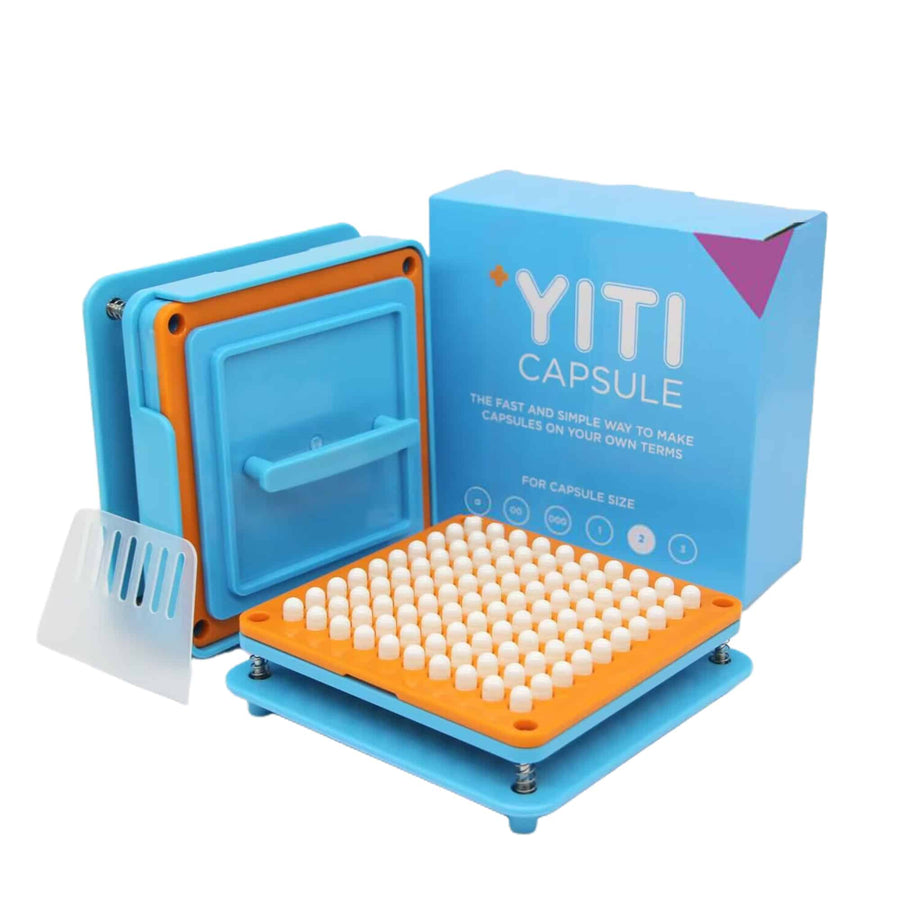

The YITI 100-hole capsule filling machine is a top-tier model engineered for small-scale production of Size 2 capsules, which hold approximately 0.37ml of powder. Its lightweight, ergonomic design and high-precision performance make it an excellent choice for professionals and home users.

Key Specifications

- Capsule Size: #2 (0.37ml)

- Material: Food-grade ABS plastic (FDA 21 CFR 177.1020 compliant)

- Weight: 1.2kg (2.65 lbs)

- Capacity: 100 capsules in 10–15 minutes

- Fill Accuracy: ±3% variance

- Dimensions: 22×15×5 cm (8.6×5.9×1.9 in)

Features That Stand Out

- Anti-static design: Prevents powder clumping

- Snap-lock assembly: No tools required

- Supports various powders: Herbal, nutritional, and cosmetic-grade materials

How the Components Work Together

Here’s a simplified step-by-step guide to using the YITI or similar hand-operated capsule filler:

- Place the alignment plate: Load empty capsules and shake to align into holes.

- Separate caps and bodies: Remove the cap tray and set aside.

- Add powder: Pour your supplement powder and use the spreader card.

- Use tamper: Compact the powder and refill if needed for max fill.

- Reattach caps: Place the cap tray on top of the body tray.

- Lock the capsules: Apply pressure using the locking plate.

- Release capsules: Use ejector plate or remove manually.

Tips for Effective Use and Maintenance

- Clean after each use: Prevent cross-contamination between batches

- Use fine powders: Coarse particles may reduce uniformity

- Keep machine dry: Especially when using herbal or hygroscopic powders

- Lubricate capsule shells (optional): With food-grade lubricant for smoother sealing

Frequently Asked Questions

What is the fill accuracy of the YITI 100-hole machine?

±3%, depending on powder consistency and tamping technique.

Can I use the machine for Size 0 or Size 1 capsules?

No. The YITI model discussed is specifically designed for Size 2 capsules. Other sizes require dedicated plates.

Is it suitable for commercial use?

Yes—for small batch production and prototyping. For high-volume commercial production, semi-automatic machines are recommended.

Summary Table: Capsule Filler Parts & Functions

| Part Name | Function | Material | Included in YITI Machine? |

|---|---|---|---|

| Base Plate | Foundation for structure | ABS Plastic | Yes |

| Alignment Plate | Aligns capsules with holes | ABS Plastic | Yes |

| Capsule Body Plate | Holds capsule bottoms | ABS Plastic | Yes |

| Capsule Cap Plate | Holds capsule tops | ABS Plastic | Yes |

| Spreader Card / Tamper | Spreads and compacts powder | ABS Plastic or Acrylic | Yes |

| Locking Plate | Locks caps and bodies | ABS Plastic | Yes |

| Ejector Plate | Releases filled capsules | ABS Plastic | Yes |