The demand for high-quality, personalized supplements is growing steadily, leading to a surge in the production of capsule filling machines. These machines play a pivotal role in the manufacturing of capsules, allowing companies and individuals alike to fill capsules with powders, herbs, vitamins, and other nutritional ingredients. Whether you're in the pharmaceutical industry, a health enthusiast, or a supplement manufacturer, understanding the different types of capsule filling machines available can help you make an informed decision based on your needs.

In this article, we will dive deep into the world of capsule filling machines, exploring the various types, their uses, and the benefits they offer to businesses and individuals. We will also highlight one of the leading machines on the market: Capsule Filling Machine - size 00 - 100 Holes

Table of Contents

- Introduction to Capsule Filling Machines

- Types of Capsule Filling Machines

- Manual Capsule Filling Machines

- Semi-Automatic Capsule Filling Machines

- Automatic Capsule Filling Machines

- Encapsulation Machines for Specific Capsule Sizes

- Key Features to Consider When Choosing a Capsule Filling Machine

- How the YITI Capsule Filling Machine Works

- Benefits of Using the YITI Capsule Filling Machine

- Common FAQs

- Conclusion

Introduction to Capsule Filling Machines

Capsule filling machines are essential tools for manufacturing and filling capsules with powders, herbs, or other substances. These machines are particularly important in industries such as pharmaceuticals, nutraceuticals, and herbal medicine, as they ensure the precise and efficient filling of capsules. With a wide range of machines available, choosing the right one for your needs depends on factors like batch size, level of automation, and the type of capsules you are filling.

In this article, we will explore the different types of capsule filling machines, their features, and how to select the best machine for your requirements.

Types of Capsule Filling Machines

Capsule filling machines come in a variety of designs, each catering to different filling needs. Whether you need to fill a few dozen capsules or thousands in a short amount of time, there is a machine suited for your needs. Let's look at the four main types of capsule filling machines:

Manual Capsule Filling Machines

Manual capsule filling machines are the most basic type of capsule filling machine. They are often used by small businesses, home users, and health enthusiasts who want to fill capsules without the need for heavy machinery.

Features of Manual Capsule Filling Machines:

- Cost-Effective: They are affordable and easy to use for small-scale production.

- Portable: These machines are compact, lightweight, and easy to transport.

- No Power Source Required: Manual machines don't require electricity, making them ideal for use in various environments.

- Ideal for Small Batches: Best suited for filling small batches, typically from 10 to 100 capsules at a time.

Best For:

- Home users

- Herbalists

- Small businesses

- Hobbyists

While manual machines may require more effort and time, they provide complete control over the filling process, making them a good option for those looking for precision and low-cost solutions.

Semi-Automatic Capsule Filling Machines

Semi-automatic capsule filling machines bridge the gap between manual and fully automatic machines. These machines are designed for medium-sized production needs, offering improved efficiency while still requiring some manual operation.

Features of Semi-Automatic Capsule Filling Machines:

- Enhanced Efficiency: These machines speed up the capsule filling process compared to manual machines.

- Partially Automated: Operators still need to perform certain tasks (e.g., loading capsules and powders), but the machine automates much of the filling process.

- Variable Capacity: Some semi-automatic machines can handle hundreds of capsules per batch.

- Easy to Operate: Requires minimal training, making them accessible to those without technical expertise.

Best For:

- Small to medium-sized manufacturers

- Those looking to scale up production without committing to a fully automatic solution

- Individuals needing to fill larger batches for personal or commercial use

While these machines still require some manual effort, their increased efficiency allows for quicker and more consistent filling, making them a valuable tool for growing businesses.

Automatic Capsule Filling Machines

Automatic capsule filling machines are designed for large-scale commercial production. These machines can fill thousands of capsules per hour and are widely used in the pharmaceutical and nutraceutical industries.

Features of Automatic Capsule Filling Machines:

- Fully Automated: From filling to sealing, these machines handle every aspect of the capsule production process.

- High-Speed Production: Can fill large quantities of capsules in a short amount of time.

- Consistent Dosage: Ensures precise and consistent filling with minimal human intervention.

- Advanced Features: Equipped with features such as automated capsule separation, powder feeding, and sealing.

Best For:

- Large-scale pharmaceutical manufacturers

- Supplement producers with high-volume production needs

- Companies requiring precise, high-speed operations

Automatic machines are typically used in environments where large quantities of capsules need to be filled quickly and accurately. While they come with a higher upfront cost, they are incredibly efficient and capable of handling high-volume production.

Encapsulation Machines for Specific Capsule Sizes

Some capsule filling machines are designed to accommodate specific capsule sizes. These machines are useful for manufacturers who need to create capsules in a variety of sizes, from smaller 00 size capsules to larger 000 size capsules.

Features of Encapsulation Machines for Specific Capsule Sizes:

- Customizable: Can handle different capsule sizes to meet specific product requirements.

- Versatile: Useful for businesses that produce a range of products in different capsule sizes.

- Precise Filling: Ensures that capsules are filled to the correct weight and dosage, even with varied capsule sizes.

Best For:

- Businesses that produce products in different capsule sizes

- Companies that require flexibility in capsule manufacturing

- Manufacturers producing specialized products with varying dosages

These machines provide flexibility and ensure that each size of capsule is filled with the correct amount of supplement, which is especially important for businesses that offer a wide variety of products.

Key Features to Consider When Choosing a Capsule Filling Machine

When selecting a capsule filling machine, there are several important factors to consider to ensure you choose the right machine for your needs. Here are the key features to keep in mind:

1. Efficiency and Output Capacity

- Consider how many capsules the machine can fill per hour or per batch. High-output machines are ideal for commercial operations, while smaller machines work better for personal use or smaller businesses.

2. Ease of Use

- Look for machines that are easy to assemble and operate. Many machines come with detailed instructions and minimal components, making them user-friendly.

3. Size and Portability

- If you're working with limited space or need to transport the machine, choose a compact, lightweight machine. The Capsule Filling Machine - size 00 - 100 Holes Holes is an excellent example of a portable, easy-to-transport machine.

4. Durability

- Ensure the machine is built from high-quality materials that will withstand frequent use without losing its efficiency. Machines made from ABS plastic or stainless steel are often durable and long-lasting.

5. Versatility

- Some machines are more versatile, allowing you to fill different capsule sizes or handle a variety of powders. This can be particularly useful if you offer multiple products.

How the YITI Capsule Filling Machine Works

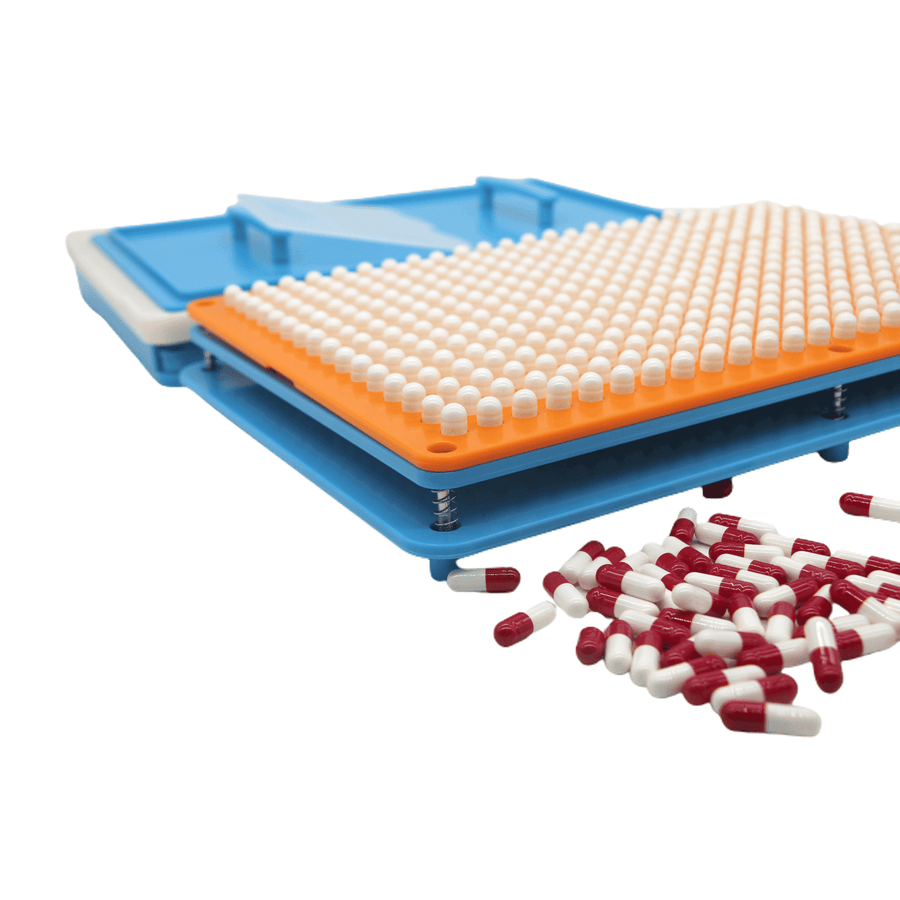

The YITI Capsule Filling Machine is a 100-hole, size 00 capsule filling machine that is designed for ease of use and efficiency. Here's a brief overview of how this machine works:

- Assembly: The machine is easy to assemble, with clear instructions provided. It comes with all the necessary tools for assembly, ensuring that you can start filling capsules quickly.

- Filling Process: The machine allows you to fill 100 capsules at a time, ensuring efficient and consistent dosage. Simply place the capsule bodies in the designated slots, add the powder, and the machine will fill the capsules with precision.

- Compact Design: The YITI machine is small, portable, and lightweight, making it an ideal option for home use or smaller businesses.

- Durable Construction: Made from high-quality ABS plastic, the machine is durable and able to withstand frequent use without degradation.

Benefits of Using the YITI Capsule Filling Machine

The YITI Capsule Filling Machine offers numerous benefits, making it an excellent choice for those in need of an efficient, portable, and durable capsule filling solution.

1. Time Efficiency

With a 100-hole capacity, this machine can fill a large number of capsules in a relatively short amount of time, making it ideal for both small businesses and personal use.

2. Accurate Dosage

The precise design of the YITI machine ensures that each size 00 capsule is filled with the correct dosage, which is crucial for supplement consistency and effectiveness.

3. Compact and Portable

Its compact design makes it easy to store and transport, so you can use it in various locations without hassle.

4. High-Quality Material

The machine is made from durable ABS plastic, ensuring that it is built to last and can handle frequent use without losing effectiveness.

Common FAQs

1. How long does it take to fill a batch of 100 capsules?

It typically takes a few minutes to fill a batch of 100 capsules, depending on your familiarity with the machine. The YITI machine is designed to be quick and efficient.

2. Is the YITI capsule filling machine easy to clean?

Yes, the YITI machine is easy to clean. Simply remove the parts that come in contact with the powder, and wash them with warm soapy water.

3. Can I use the YITI capsule filling machine for different capsule sizes?

The YITI machine is designed for size 00 capsules, but there are other machines available that can handle different sizes.

Conclusion

Choosing the right capsule filling machine depends on your needs, whether you're a health enthusiast, small business owner, or large manufacturer. The Capsule Filling Machine - size 00 - 100 Holes offers an efficient, compact, and affordable solution for those who need precise capsule filling. By understanding the different types of capsule filling machines available and considering your specific requirements, you can make an informed decision and invest in a machine that helps you produce high-quality, consistent capsules.