Table of Contents

- Introduction

- Manual Capsule Filling Machines

- Semi-Automatic Capsule Filling Machines

- Fully Automatic Capsule Filling Machines

- Capsule Filling Machines for Liquid and Oil-Based Formulations

- Summary Table

Introduction

Capsule filling machines are essential equipment in the pharmaceutical and nutraceutical industries, enabling efficient and accurate encapsulation of various substances. Depending on production scale, budget, and specific requirements, different types of capsule filling machines are available. This guide explores four primary types: manual, semi-automatic, fully automatic, and machines designed for liquid and oil-based formulations.

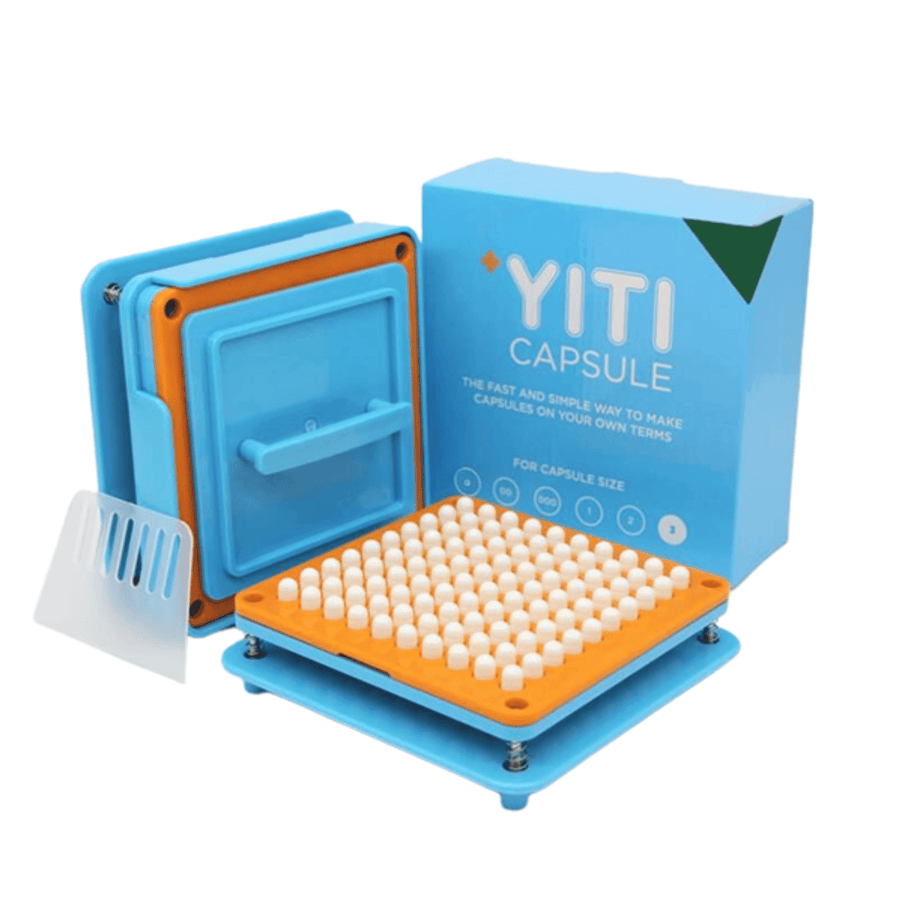

Manual Capsule Filling Machines

Manual capsule filling machines are ideal for small-scale production, research and development, or personal use. They are cost-effective and allow for hands-on control over the encapsulation process.

Features

- Capacity: Typically accommodates 100 to 300 capsules per batch.

- Operation: Requires manual loading, filling, and sealing of capsules.

- Material Compatibility: Suitable for powders and granules.

Advantages

- Cost-Effective: Low initial investment.

- Simple Maintenance: Easy to clean and maintain.

- Portability: Compact and lightweight design.

Limitations

- Labor-Intensive: Requires significant manual effort.

- Lower Throughput: Not suitable for large-scale production.

- Consistency: Potential for variability in capsule fill weight.

Semi-Automatic Capsule Filling Machines

Semi-automatic capsule filling machines bridge the gap between manual and fully automatic machines, offering increased efficiency while retaining some manual control.

Features

- Capacity: Can fill up to 25,000 capsules per hour, depending on the model and operator proficiency.

- Operation: Automated capsule orientation and separation; manual or automated powder filling.

- Material Compatibility: Suitable for powders, granules, and some pellets.

Advantages

- Increased Efficiency: Higher output compared to manual machines.

- Flexibility: Allows for adjustments and control over the filling process.

- Cost-Effective: Lower investment than fully automatic machines.

Limitations

- Operator Dependency: Requires skilled operators for optimal performance.

- Maintenance: More complex than manual machines, requiring regular maintenance.

Fully Automatic Capsule Filling Machines

Fully automatic capsule filling machines are designed for high-volume production, offering precision and efficiency with minimal human intervention.

Features

- Capacity: Capable of filling up to 300,000 capsules per hour, depending on the model.

- Operation: Automated capsule loading, separation, filling, and sealing processes.

- Material Compatibility: Suitable for powders, granules, pellets, and some liquids.

Advantages

- High Efficiency: Ideal for large-scale production.

- Consistency: Ensures uniform fill weight and capsule quality.

- Labor Savings: Reduces the need for manual labor.

Limitations

- High Initial Investment: Significant capital expenditure required.

- Complex Maintenance: Requires specialized knowledge for maintenance and troubleshooting.

Capsule Filling Machines for Liquid and Oil-Based Formulations

Specialized capsule filling machines are designed to handle liquid and oil-based formulations, often used in the production of softgel capsules.

Features

- Encapsulation: Utilizes rotary die technology for seamless capsule formation.

- Material Compatibility: Suitable for oils, suspensions, and other liquid formulations.

- Integration: Often integrated with drying and polishing systems.

Advantages

- Versatility: Allows encapsulation of a wide range of liquid substances.

- Product Stability: Protects sensitive ingredients from oxidation and degradation.

- Consumer Preference: Softgel capsules are often preferred for ease of swallowing.

Limitations

- Specialized Equipment: Requires specific machinery and expertise.

- Higher Costs: Increased production and material costs compared to hard capsules.

Summary Table

| Machine Type | Capacity | Operation | Advantages | Limitations |

|---|---|---|---|---|

| Manual | Up to 300 capsules/batch | Fully manual | Low cost, simple maintenance | Labor-intensive, low throughput |

| Semi-Automatic | Up to 25,000 capsules/hour | Partial automation | Increased efficiency, flexibility | Operator dependency, maintenance |

| Fully Automatic | Up to 300,000 capsules/hour | Fully automated | High efficiency, consistency | High investment, complex maintenance |

| Liquid/Oil-Based | Varies | Specialized automation | Versatility, product stability | Specialized equipment, higher costs |

::contentReference[oaicite:84]{index=84}