Table of Contents

- Introduction

- What is a Semi-Automatic Capsule Filling Machine?

-

Working Principle of a Semi-Automatic Capsule Filling Machine

- 3.1 Machine Overview

- 3.2 Step-by-Step Process

- 3.3 Key Components

- Benefits of Using a Semi-Automatic Capsule Filling Machine

-

YITI Capsule Filling Machine: Features and Advantages

- 5.1 Creative with Custom Capsules

- 5.2 Simplify Your Supplement Routine

- 5.3 Precision and Consistency

- 5.4 Safe and Durable Design

- 5.5 Versatile and Affordable

- Common Challenges in Capsule Filling and Solutions

- FAQs

- Conclusion

Introduction

As the health and wellness industry continues to expand, the demand for tailored supplement solutions is on the rise. Semi-automatic capsule filling machines have emerged as a practical and efficient tool, enabling manufacturers, health enthusiasts, and small businesses to produce customized supplements, medications, and nutraceutical products. This article delves into the working principles of these machines, examining their functionality, key components, and the advantages they offer.

What is a Semi-Automatic Capsule Filling Machine?

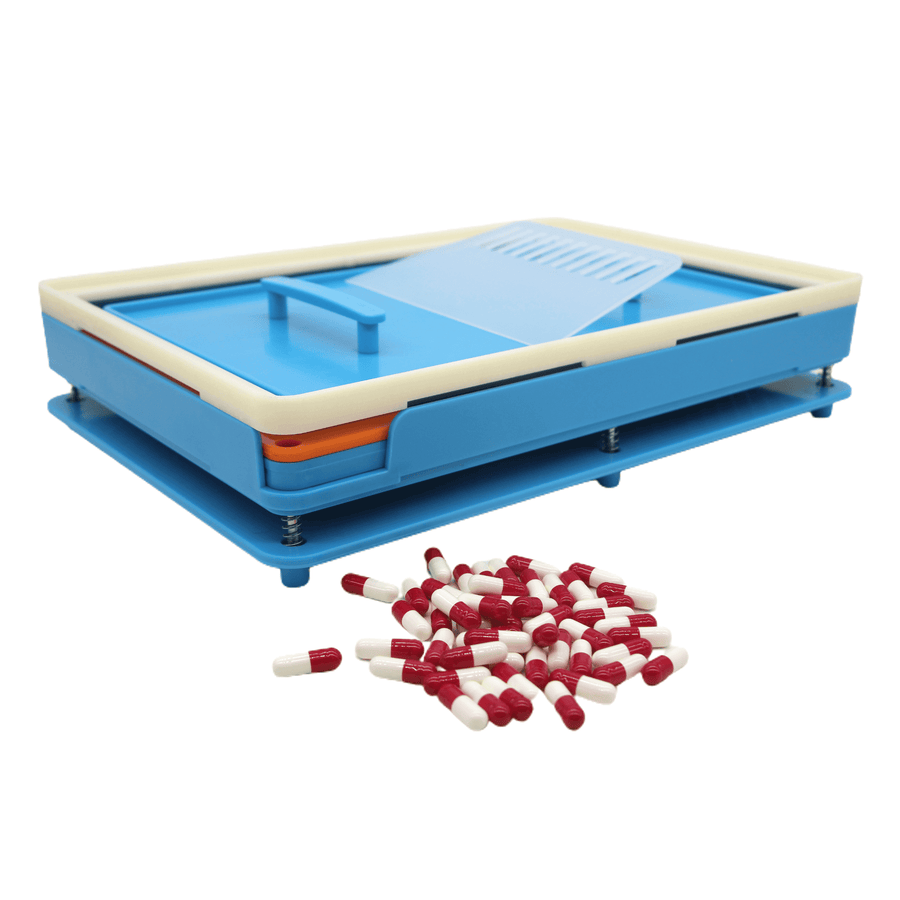

A semi-automatic capsule filling machine is a device used to fill empty capsules with powdered ingredients, supplements, or medications. Unlike fully automatic machines, semi-automatic models require manual intervention at certain stages of the process, though they significantly reduce the labor and time needed to fill capsules compared to manual methods. These machines are ideal for small to medium-scale production and are used by supplement manufacturers, pharmacies, and individuals looking to create their own capsules at home.

Working Principle of a Semi-Automatic Capsule Filling Machine

The working principle of a semi-automatic capsule filling machine revolves around the process of separating empty capsules, filling them with the desired powder or granules, and then sealing the capsules. While the machine is not fully automated, it simplifies the process and ensures consistency in filling.

3.1 Machine Overview

A typical semi-automatic capsule filling machine consists of a few main components that facilitate its operation:

- Capsule Holder: This is where the empty capsules are placed for filling.

- Powder Filling Station: The section of the machine where the powder or granules are inserted into the capsules.

- Capsule Closing Mechanism: A mechanism that seals the capsules after they are filled, ensuring that they remain intact.

- Adjustment Controls: These controls help operators adjust the machine settings, such as filling amount and capsule size.

3.2 Step-by-Step Process

- Preparation: The operator first places empty capsules into the machine’s capsule holder. The machine can accommodate various capsule sizes depending on the model.

- Separation: The machine then separates the capsule shells into two parts: the body and the cap.

- Filling: Once the capsules are separated, the operator places the powder into the machine’s filling station. A plunger or piston pushes the powder into the capsule body. This is often done with precision to ensure that each capsule receives the correct amount of product.

- Capsule Closing: After filling, the capsules are then placed back together by the closing mechanism. This seals the capsules tightly to prevent spillage of the contents.

- Ejection: The filled capsules are then ejected from the machine and ready for packaging.

This process can be adjusted depending on the type of product being filled and the capacity of the machine.

3.3 Key Components

- Capsule Tray: Holds the empty capsules in place before filling.

- Powder Hopper: Stores the powder that will be used to fill the capsules.

- Filling Needle: A device that helps control the amount of powder dispensed into the capsule.

- Compression Plate: Ensures the powder is packed tightly into the capsule body.

- Capsule Ejection System: Removes the finished capsules from the machine once the filling and sealing processes are complete.

These components work in tandem to automate much of the capsule filling process, reducing the labor required while maintaining a high level of accuracy and consistency.

Benefits of Using a Semi-Automatic Capsule Filling Machine

There are numerous advantages to using a semi-automatic capsule filling machine, whether you are a small-scale producer or an individual looking to create your own custom supplements.

1. Efficiency and Speed

A semi-automatic capsule filling machine significantly speeds up the process compared to manual filling. The machine can fill a large number of capsules in a short period, which is crucial for businesses that need to maintain production efficiency.

2. Consistency and Precision

One of the key benefits of using a semi-automatic machine is the precision it offers. Since the machine is designed to dispense a consistent amount of powder into each capsule, it ensures uniformity in the final product. This is particularly important for ensuring that each capsule contains the correct dosage of ingredients.

3. Customization

With a semi-automatic capsule filling machine, you can get creative with your supplement creation. The machine allows you to combine different ingredients and dosages for personalized results. Whether you're making vitamins, herbs, or any other type of supplement, you can tailor each capsule to meet specific health needs.

4. Cost-Effective

Using a semi-automatic capsule filling machine is a cost-effective solution, particularly for small businesses or home-based supplement manufacturers. The machine provides a high level of automation at a lower cost compared to fully automatic machines, making it accessible to a wider range of users.

5. Safe and Durable

Semi-automatic machines are built with high-quality materials and advanced technology, ensuring they are safe to use and durable over time. This makes them a good investment for businesses or individuals who need a reliable solution for filling capsules regularly.

YITI Capsule Filling Machine: Features and Advantages

YITI offers a 400-hole capsule filling machine that has been designed with both efficiency and creativity in mind. Below are some of the standout features and advantages of this product:

5.1 Creative with Custom Capsules

The YITI 400-hole capsule filling machine allows users to be creative with their supplement creations. With the ability to combine different ingredients, dosages, and capsule sizes, you can craft personalized capsules to meet specific health goals.

5.2 Simplify Your Supplement Routine

Gone are the days of manual capsule filling. The YITI machine simplifies the process, allowing you to fill 400 capsules at once, reducing the time and effort required to create your supplements.

5.3 Precision and Consistency

YITI’s 400-hole machine ensures that each capsule is filled with the same amount of powder, ensuring accuracy and consistency across every batch. This is critical for creating products that meet specific dosage requirements.

5.4 Safe and Durable Design

Crafted with top-quality materials, the YITI capsule filling machine is built to last. The machine’s design prioritizes user safety, and it is made to withstand the rigors of regular use in a supplement creation environment.

5.5 Versatile and Affordable

The YITI machine is an affordable option for anyone looking to create their own supplements at home or on a small scale. Its versatility allows it to handle a variety of ingredients, and its easy-to-use design makes it accessible for beginners.

Common Challenges in Capsule Filling and Solutions

While semi-automatic capsule filling machines are highly efficient, they are not without their challenges. Here are some common issues and solutions:

-

Problem: Powder Spillage

Solution: Ensure that the powder is filled properly into the hopper, and check that the filling mechanism is working as intended. Using a high-quality powder hopper and filling needle can also help minimize spillage. -

Problem: Capsules Not Sealing Properly

Solution: If the capsules are not sealing correctly, check the alignment of the capsule closing mechanism. Ensure that the machine is calibrated to handle the specific size of capsules being used. -

Problem: Inconsistent Filling

Solution: Regularly calibrate the filling system to ensure consistent dispensing of powder. Make sure the compression plate is working correctly to pack the powder evenly into each capsule.

FAQs

1. How does a semi-automatic capsule filling machine work?

A semi-automatic capsule filling machine works by separating the capsule shells, filling them with powder, and then sealing the capsules. The process is partially automated, requiring manual intervention at some stages.

2. What types of ingredients can I use with a capsule filling machine?

You can use a variety of ingredients, including herbal powders, vitamins, minerals, and other nutraceuticals. The machine works best with powders or granules that can be compacted into the capsule body.

3. Can I use the YITI capsule filling machine for large-scale production?

The YITI capsule filling machine is designed for small to medium-scale production, making it perfect for home use, small businesses, or supplement enthusiasts. For large-scale production, you may need to consider a fully automatic machine.

Conclusion

A semi-automatic capsule filling machine is an essential tool for anyone involved in creating custom supplements, medications, or nutraceuticals. The machine simplifies the process, ensuring precision and efficiency while allowing for the flexibility to create personalized capsules. With the YITI 400-hole capsule filling machine, users can enjoy the benefits of a high-quality, affordable, and user-friendly product that enhances the supplement creation process. Whether you're a health enthusiast or a small business owner, this machine offers an accessible and effective solution for all your capsule filling needs.