Table of Contents

- Introduction

- 1. Manual Capsule Filling

- 2. Semi-Automatic Capsule Filling

- 3. Automatic Capsule Filling

- 4. Capsule Filling by Auger Filling System

- 5. Tamping Pin Capsule Filling

- YITI Capsule Filling Machine – A Recommended Solution

- Conclusion

- Summary Table

Introduction

Capsule filling is a crucial process in pharmaceutical, nutraceutical, and supplement production. The right technique ensures that capsules are accurately filled, maintaining dosage precision, efficiency, and safety. Whether for small-scale home use or large-scale industrial production, there are several effective techniques available.

In this article, we will explore the five most appropriate techniques for filling capsules, along with a recommended capsule filling machine that enhances efficiency and accuracy.

1. Manual Capsule Filling

Manual capsule filling is a simple and cost-effective method, especially for small-scale production or personal use.

How It Works:

- The capsule is separated into two halves.

- The powder or supplement is carefully placed into the longer half of the capsule.

- The shorter half is then pressed onto the filled portion, securing the contents.

Advantages:

- Low cost – No expensive equipment required.

- Simple and easy – Ideal for beginners or small-scale supplement makers.

- Allows customization – Users can manually adjust ingredients and dosages.

Disadvantages:

- Time-consuming – Filling each capsule individually can be slow.

- Inconsistent filling – Variation in capsule weights and dosages.

Best for:

✔ Home users and small supplement businesses.

✔ Individuals who want full control over their capsule ingredients.

2. Semi-Automatic Capsule Filling

Semi-automatic capsule filling machines increase efficiency by handling parts of the process automatically while still requiring some manual input.

How It Works:

- The capsules are loaded into a holding tray.

- The machine separates the capsules automatically.

- Powder is dispensed into the capsule body using a controlled system.

- The top half of the capsule is aligned and closed manually.

Advantages:

- Faster than manual filling – Can fill hundreds of capsules at once.

- More consistent dosing than hand-filling.

- Lower cost compared to fully automatic machines.

Disadvantages:

- Requires some manual work.

- Not as fast as fully automatic machines.

Best for:

✔ Small to mid-sized businesses.

✔ Those needing higher efficiency but with lower budgets.

3. Automatic Capsule Filling

Automatic capsule filling machines are designed for high-speed production, used in large-scale manufacturing of pharmaceuticals and supplements.

How It Works:

- Capsules are automatically sorted, separated, and filled with powder.

- The filling process uses precise measurement systems for accuracy.

- Capsules are closed and ejected into a collection bin.

Advantages:

- Extremely fast – Can fill thousands of capsules per hour.

- Highly precise dosage control.

- Minimal manual labor required.

Disadvantages:

- Expensive investment.

- Requires technical knowledge for operation and maintenance.

Best for:

✔ Large pharmaceutical and supplement manufacturers.

✔ Businesses with high production demands.

4. Capsule Filling by Auger Filling System

The auger filling system is commonly used in industrial production and ensures high precision in powder filling.

How It Works:

- A rotating auger moves the powder into the capsules.

- The powder is measured in precise amounts before being dispensed.

- Capsules are automatically sealed and ejected.

Advantages:

- Highly accurate dosing – Reduces material waste.

- Fast and efficient – Suitable for industrial applications.

- Works with different capsule sizes.

Disadvantages:

- Expensive machinery.

- Not suitable for home or small business use.

Best for:

✔ Large-scale supplement or pharmaceutical manufacturers.

5. Tamping Pin Capsule Filling

The tamping pin method is widely used in the pharmaceutical industry for compacting powders into capsules.

How It Works:

- Powder is spread evenly into a capsule tray.

- Tamping pins press the powder into each capsule to achieve uniform density.

- The top half of the capsule is sealed and ejected.

Advantages:

- More compact and uniform capsules.

- Works well for fine powders.

- Reduces air pockets that could affect dosage.

Disadvantages:

- Complex machinery – Requires maintenance.

- Not suitable for low-budget operations.

Best for:

✔ Pharmaceutical companies requiring consistent capsule density.

YITI Capsule Filling Machine – A Recommended Solution

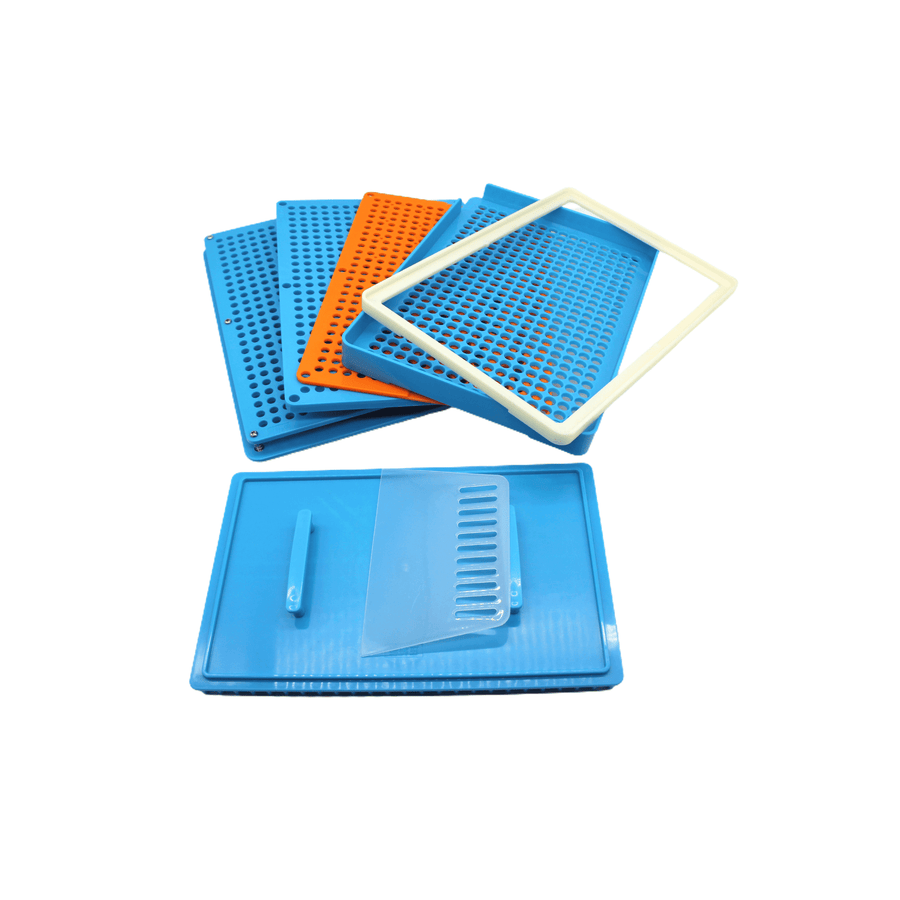

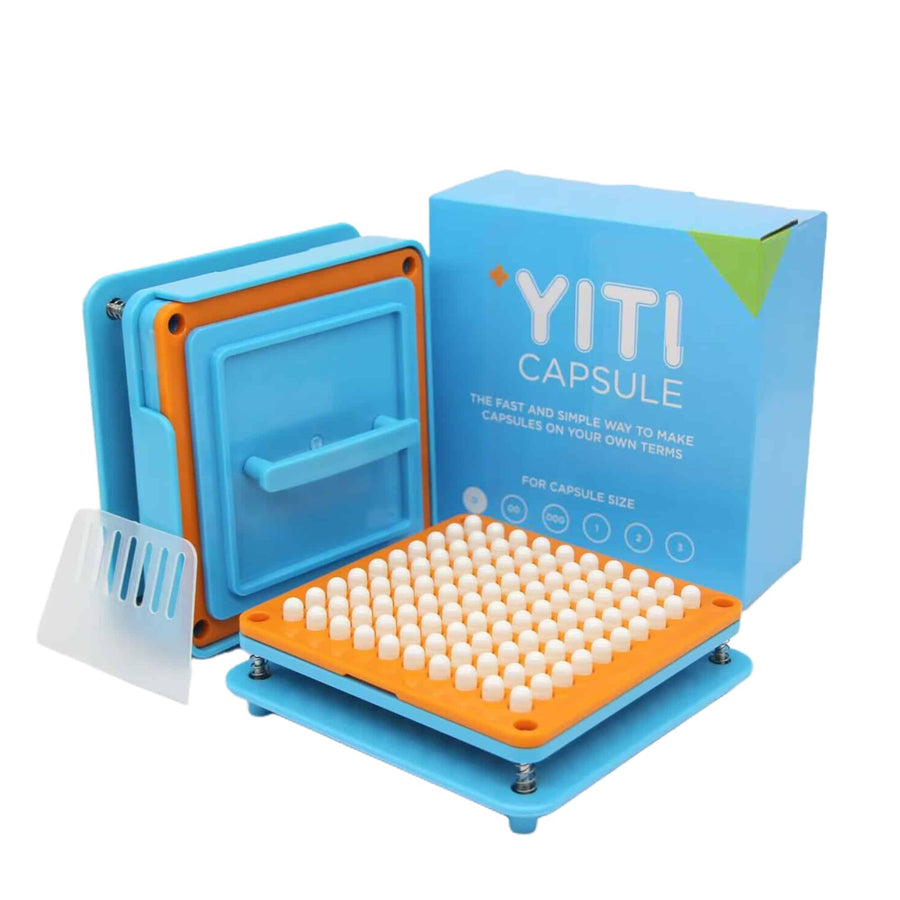

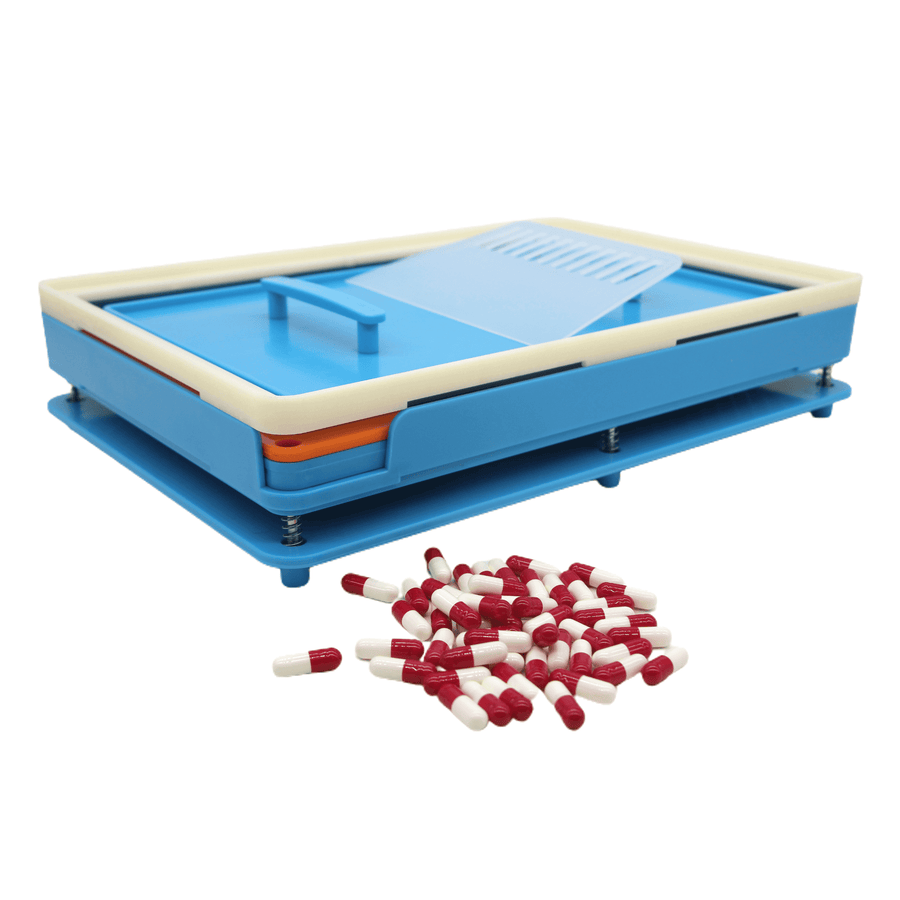

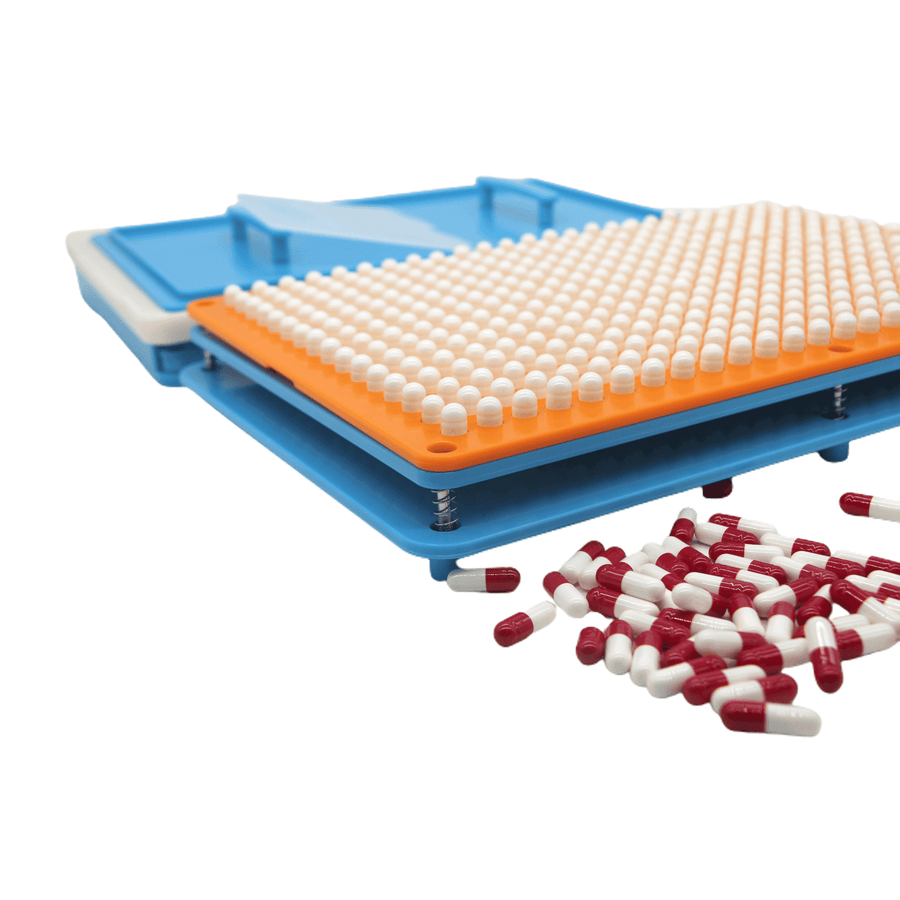

For small-scale supplement makers, a semi-automatic capsule filling machine is an excellent balance between affordability and efficiency.

YITI Capsule Filling Machine - Size 00 - 400 Holes

✔ Custom Capsule Creation: Create unique supplement combinations tailored to specific health needs.

✔ Efficient & User-Friendly: Speeds up capsule filling, making it easier than manual methods.

✔ Precision & Consistency: Ensures accurate dosages in each capsule.

✔ Durable Design: Made with high-quality materials for long-term use.

✔ Affordable & Versatile: A great investment for those who want control over their supplement production.

This machine is ideal for:

- Small businesses producing health supplements.

- Individuals making personalized vitamin or herbal capsules.

- Researchers or professionals creating test batches of supplements.

Conclusion

Choosing the right capsule filling technique depends on your production scale, budget, and accuracy needs.

- Manual capsule filling is best for small, customized batches.

- Semi-automatic machines balance efficiency and affordability.

- Automatic and industrial techniques like auger filling or tamping pin systems are suited for high-volume production.

If you're looking for an affordable, efficient solution, the YITI Capsule Filling Machine is a great option to speed up the process while maintaining quality and consistency.

Summary Table

| Filling Method | Speed | Accuracy | Best For | Cost |

|---|---|---|---|---|

| Manual Capsule Filling | Slow | Low | Home use & small batches | Low |

| Semi-Automatic Filling | Moderate | Moderate | Small businesses | Medium |

| Automatic Filling | Fast | High | Large-scale production | High |

| Auger Filling System | Very Fast | Very High | Industrial use | Very High |

| Tamping Pin Method | Fast | High | Pharmaceutical industry | High |

By choosing the right technique, you can maximize efficiency and ensure precise supplement dosing for your needs! 🚀