Introduction to Soft Gel Encapsulation Machines

Soft gel encapsulation machines are used to produce soft gel capsules, a popular form of oral medication, dietary supplements, and even cosmetic products. Soft gels are known for their smooth, easy-to-swallow texture and precise dosage, making them a preferred choice in many industries. The encapsulation process involves the mixing of active ingredients with a gelatinous base and encapsulating them in a soft, transparent shell.

In 2025, the demand for soft gel encapsulation machines has continued to grow as businesses seek more efficient and cost-effective ways to produce high-quality soft gel capsules. This article will explore the factors influencing the cost of soft gel encapsulation machines, price ranges for different types, and top recommendations to consider for your business.

Factors Affecting the Cost of Soft Gel Encapsulation Machines

The price of a soft gel encapsulation machine depends on several factors that affect its functionality, capacity, and overall value. Understanding these factors is crucial when choosing the right machine for your needs, whether you're a small business or a large-scale manufacturer.

2.1. Machine Size and Capacity

The size and capacity of a soft gel encapsulation machine are among the most significant factors affecting its price. Smaller machines are typically used for low to medium production volumes, while larger machines are designed for high-volume production. The size and number of capsules a machine can fill per cycle also impact its price.

- Smaller machines: Often used for lab-scale production or small businesses, these machines have lower capacities, typically filling fewer capsules per cycle. As a result, their cost is generally more affordable.

- Larger machines: High-capacity machines are built for mass production and can fill thousands of capsules per hour. These machines are more expensive due to their size, automation capabilities, and the complexity of their systems.

2.2. Automation Level

The automation level of the machine plays a significant role in determining its price. Manual, semi-automatic, and fully automatic machines are available, each with varying degrees of automation.

- Manual machines: These are basic machines that require manual intervention at each stage of the encapsulation process. They are ideal for small-scale or experimental production and are typically the least expensive.

- Semi-automatic machines: These machines automate certain stages of the process, such as filling capsules and closing the gelatin shell, while still requiring some manual input. Semi-automatic machines offer a balance of cost and efficiency.

- Fully automatic machines: These are the most expensive machines, as they handle the entire encapsulation process with minimal human intervention. They are used for large-scale, continuous production and come with sophisticated controls and higher production rates.

2.3. Material and Build Quality

The materials used in the construction of the machine can significantly influence the price. High-quality stainless steel, for instance, offers durability, resistance to corrosion, and ease of cleaning. Machines made from premium materials are often priced higher but offer better longevity and performance.

- Stainless steel construction is a common choice for industrial-grade machines because of its strength and durability.

- Plastic or lower-grade materials may be used in cheaper models, which can reduce the cost but may affect the machine’s long-term performance and maintenance needs.

2.4. Brand Reputation and Support

The reputation of the manufacturer and the support services offered can also affect the cost. Well-known brands with a proven track record of quality and customer service may charge a premium for their machines. However, these brands often provide better warranties, technical support, and after-sales service, which can justify the higher upfront cost.

What Are Soft Gel Encapsulation Machines Used For?

Soft gel encapsulation machines are primarily used in industries such as pharmaceuticals, nutraceuticals, and cosmetics to produce soft gel capsules that contain various active ingredients. These machines are designed to fill gelatin or non-gelatin capsules with a liquid or paste-like substance, creating a smooth, uniform product.

- Pharmaceutical industry: Soft gels are commonly used for medications, vitamins, and supplements due to their high bioavailability and ease of swallowing.

- Cosmetics industry: Soft gel capsules are also used for cosmetic products like oils, serums, and other treatments, as they provide controlled release and precise dosage.

- Food industry: Nutraceuticals and functional foods, such as omega-3 oils, CBD supplements, and herbal extracts, are often encapsulated in soft gels for ease of consumption.

Price Range of Soft Gel Encapsulation Machines in 2025

The price of a soft gel encapsulation machine can vary significantly based on the features, capacity, and level of automation. Below are the general price ranges based on different types of soft gel encapsulation machines:

4.1. Manual Machines

Manual soft gel encapsulation machines are typically the most affordable. These machines are ideal for small-scale production or startups that need low-volume output. They require more labor and human intervention but can be a good entry point for those new to the encapsulation process.

- Price Range: $200 to $2,000

4.2. Semi-Automatic Machines

Semi-automatic machines automate parts of the encapsulation process but still require manual intervention for some stages. These machines offer a balance between affordability and efficiency and are suitable for medium-scale operations.

- Price Range: $2,000 to $15,000

4.3. Fully-Automatic Machines

Fully automatic soft gel encapsulation machines are designed for high-volume production and offer the best efficiency. They are equipped with advanced features like automated filling, closing, and drying, and require minimal human intervention.

- Price Range: $15,000 to $100,000+

Top Soft Gel Encapsulation Machines in 2025

Several companies produce soft gel encapsulation machines, each offering various models with different features. Let’s take a look at two popular options available in 2025.

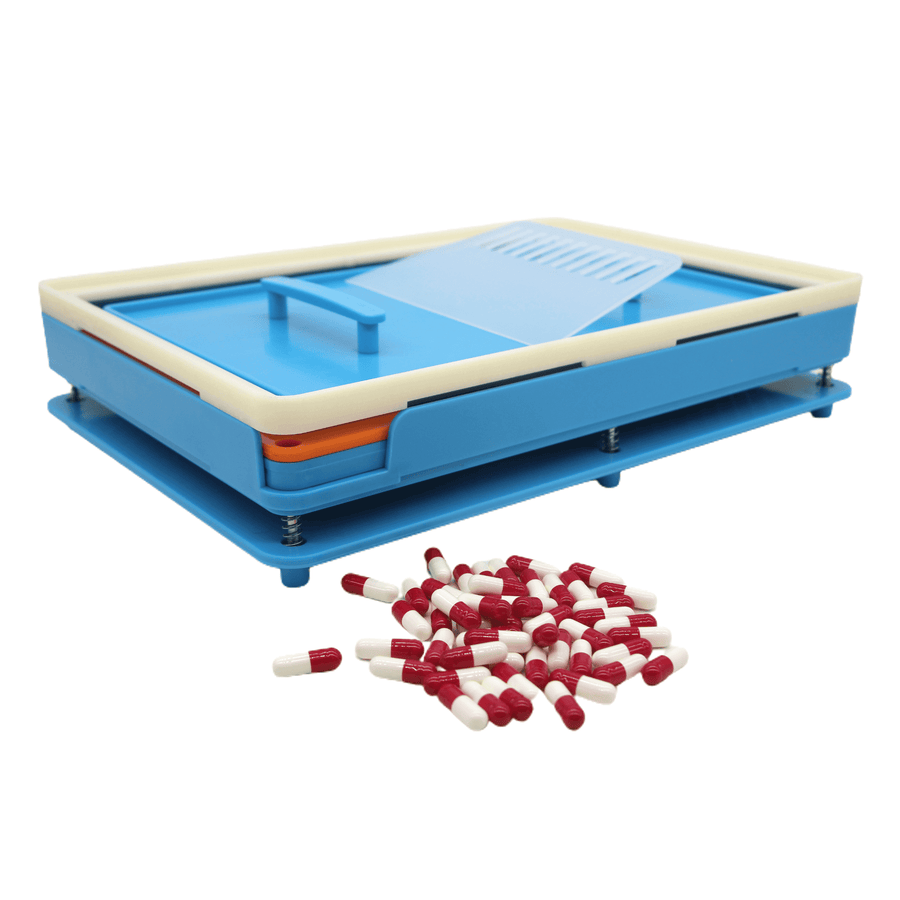

5.1. YITI Capsule Filling Machine

YITI Capsule Filling Machines are widely recognized for their durability and affordability. These machines come in various sizes and capacities, making them suitable for small to medium-scale production.

Models:

-

YITI Capsule Filling Machine - Size 00 - 100 holes

- Price: $38.95

- Features: Manual operation, small capacity (100 holes per cycle), suitable for small businesses or laboratories.

-

YITI Capsule Filling Machine - Size 00 - 400 holes

- Price: $149.99

- Features: Increased capacity (400 holes per cycle), ideal for medium-scale production, more efficient than smaller models.

YITI machines offer a good balance of affordability and efficiency, making them ideal for those who are starting small or need to scale up production without a huge upfront investment.

Cost Breakdown of YITI Capsule Filling Machines

Here is a quick comparison of the YITI Capsule Filling Machines based on their price and features:

| Model | Price | Capacity | Suitable For | Key Features |

|---|---|---|---|---|

| YITI Capsule Filling Machine - Size 00 (100 holes) | $38.95 | 100 holes per cycle | Small businesses/laboratories | Manual operation, compact design |

| YITI Capsule Filling Machine - Size 00 (400 holes) | $149.99 | 400 holes per cycle | Medium-scale production | Semi-automatic, increased efficiency |

Common FAQ About Soft Gel Encapsulation Machines

1. What is the main difference between manual and automatic soft gel encapsulation machines?

Manual machines require manual operation and intervention at every stage of the encapsulation process, whereas automatic machines handle the entire process with minimal human input, offering higher efficiency and larger output.

2. Are soft gel encapsulation machines easy to maintain?

Maintenance depends on the complexity of the machine. Manual and semi-automatic machines require less maintenance, while fully automatic machines may need more attention, especially when it comes to cleaning and troubleshooting. Always follow the manufacturer’s guidelines to ensure long-term durability.

3. What is thelifespan of a soft gel encapsulation machine?

The lifespan varies based on usage, maintenance, and the quality of the machine. Generally, well-maintained machines can last for 5 to 10 years. Regular servicing and proper handling can extend their operational life.

Conclusion: Making the Right Decision for Your Business

Choosing the right soft gel encapsulation machine is crucial for your business's efficiency and growth. Factors such as capacity, automation level, material quality, and the machine’s price all play a significant role in determining the best option for your needs. Whether you are just starting or looking to scale up, there are machines available at various price points that cater to different production requirements.

By understanding your needs and selecting the right machine, you can ensure that your soft gel production process runs smoothly and efficiently for years to come.