Table of Contents

- Introduction

- Why Capsule Filling Machines Matter

- Benefits of Using a Capsule Filling Machine

- Criteria for Choosing the Best Capsule Filling Machine

- Top 10 Capsule Filling Machines

- YITI Capsule Filling Machine Highlights

- How to Optimize Your Supplement Production

- Maintaining Your Capsule Filling Machine

- Conclusion

- Summary Table

Introduction

In today’s fast‐paced world of health and wellness, controlling the quality and dosage of your supplements is essential. The use of capsule filling machines can significantly streamline your production—whether for personal use or a professional chemist warehouse setting. This article provides an in-depth look at the 10 best capsule filling machines available, with an emphasis on features, reliability, and practicality. We also highlight the YITI Capsule Filling Machine – a top choice for filling size 000 capsules—so that you can make an informed purchase decision.

Capsule filling machines are becoming increasingly popular among health enthusiasts, herbalists, and small business owners alike. They are the perfect tools for ensuring that each capsule is uniformly filled, guaranteeing accurate dosage and higher safety standards. In a competitive market, having the right equipment can mean the difference between a consistent product and one that fails to meet consumer expectations.

Why Capsule Filling Machines Matter

The need for precision in supplement production has grown in line with consumer demand for quality and safety. For manufacturers and health professionals, capsule filling machines not only boost efficiency but also ensure that each capsule is filled to the exact specified amount. This level of control contributes to:

- Consistent Dosage: Avoiding errors that can compromise the health benefits of a supplement.

- Enhanced Productivity: Enabling high-volume production with minimum human intervention.

- Cost Efficiency: Reducing waste and ensuring timely production runs.

- Improved Quality Control: Maintaining high standards throughout the manufacturing process.

Understanding these points underscores why investing in the right capsule filling machine is a crucial step toward a successful supplement business.

Benefits of Using a Capsule Filling Machine

Using a capsule filling machine instead of manual methods yields multiple benefits:

- Time-Saving: Automated operations significantly cut down on production time.

- Accuracy: Each capsule is filled with precision, ensuring consistent supplement strength.

- Ease of Use: Machines are designed for user-friendliness, allowing even novices to produce quality capsules.

- Versatility: Suitable for various capsule sizes and types of supplements.

- Scalability: Ideal for home-based operations as well as larger commercial production.

These benefits ultimately translate to better quality control and a more efficient production process that appeals to both individual users and bulk manufacturers.

Criteria for Choosing the Best Capsule Filling Machine

When deciding which capsule filling machine best fits your needs, consider these critical factors:

- Capacity: How many capsules can be filled in one batch? Machines vary from small, home-use models to large-scale production lines.

- Material Quality: Look for durable construction materials like high-quality ABS plastic or metal components for longevity.

- Accuracy and Consistency: The machine’s design should ensure uniformity in capsule fill levels.

- Ease of Assembly and Operation: A user-friendly interface and clear instructions mean less downtime during setup.

- Customization Options: The ability to adjust settings, such as dosage and capsule size compatibility, can be vital.

- Support and Warranty: Look for manufacturers who offer technical support, free samples for prototypes, and guarantees of on-time delivery.

Selecting a machine that checks these boxes ensures smooth operation and a reliable outcome whether for personal health, a small chemist warehouse, or more extensive manufacturing.

Top 10 Capsule Filling Machines

Here are the top 10 capsule filling machines, each offering unique features and capabilities to meet diverse production needs.

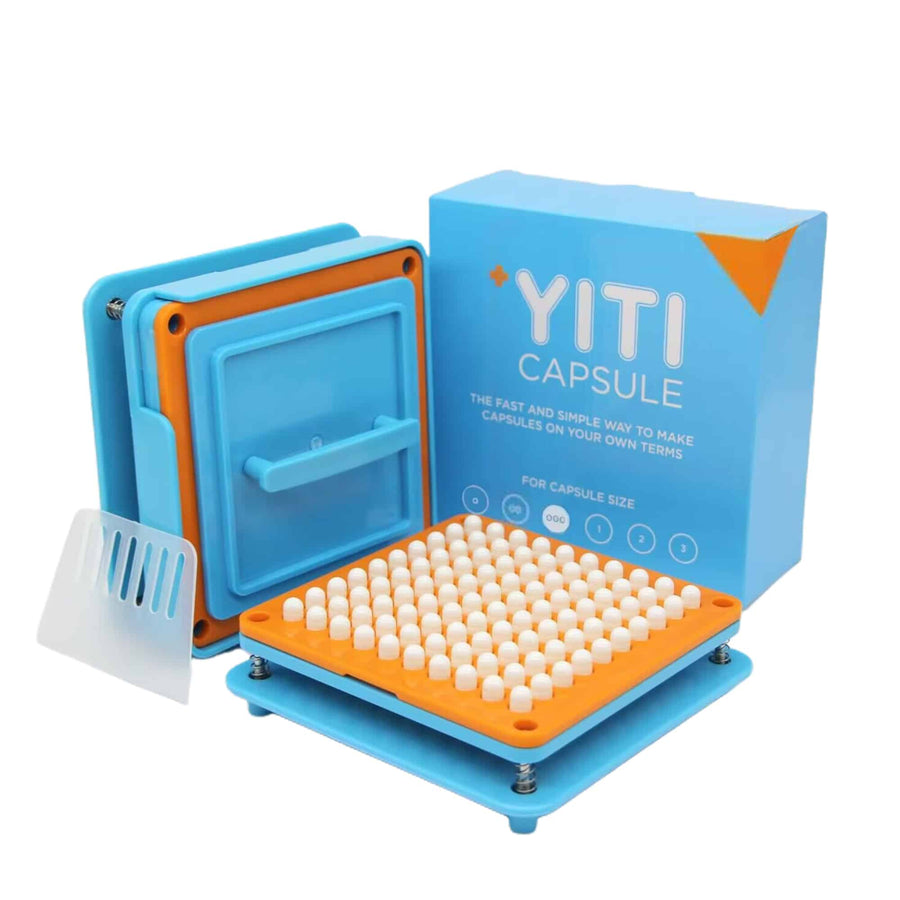

1. YITI Capsule Filling Machine – Size 000 – 100 Holes

- Efficient and Accurate: This 100-hole home capsule filling machine is perfect for size 000 capsules and ensures a precise dosage for each capsule.

- Compact and Portable: Its small dimensions and lightweight design make it easy to carry and use in different locations.

- Easy to Assemble: With simple design and clear instructions, you can get started in no time.

- High Quality Material: Made of durable ABS that ensures long-term functionality even with frequent use.

- Multifunction: Suitable for health enthusiasts and herbalists alike, the YITI machine is ideal for both personal and professional use.

2. Capsule Master 2000

- High Throughput: Capable of filling up to 2000 capsules per hour.

- User-Friendly Interface: Intuitive controls allow for quick adjustments and production calibration.

- Robust Construction: Made with high-grade materials to ensure a long operating life.

3. PharmaFill Pro

- Precision Mechanics: Designed for pharmaceutical-grade capsules with impeccable accuracy.

- Automated Operation: Features motorized operation for higher production volumes.

- Compliance: Meets strict regulatory standards for supplement manufacturing.

4. EasyFill Express

- Speed and Efficiency: Excellent for quick fill cycles without sacrificing consistency.

- Portable Design: Compact design ideal for on-the-go production.

- Cost-Effective: Provides an affordable alternative for small businesses or personal use.

5. AutoCap Pro

- Advanced Automation: Incorporates sensors and automated weighing systems for precision.

- Adaptable: Suitable for various capsule sizes beyond 000, making it versatile for multiple applications.

- Industrial Strength: Built to handle higher production requirements.

6. SmartCaps E-Series

- Intelligent Control: Uses digital displays for real-time monitoring and adjustments.

- Efficiency Boost: Reduces manual errors and downtime during production.

- Quality Assurance: Ensures every capsule meets stringent standards.

7. NutriFill 500

- Optimized for Health Supplements: Special design for nutritional and herbal capsules.

- Ergonomic Setup: Simple to use and clean, enhancing production hygiene.

- Flexible Production: Suitable for both large batches and custom small runs.

8. PrecisionCaps Elite

- Superior Accuracy: Engineered to fill capsules with exact dosages every time.

- Streamlined Workflow: Designed to integrate seamlessly with other production equipment.

- High Quality: Made with reinforced components to reduce wear and tear.

9. CapsuleFiller X

- Versatile Operation: Handles a range of capsule sizes and materials.

- Automated Dispensing: Offers fully automated filling for maximum production efficiency.

- Warranty and Support: Backed by a robust customer service network and warranty period.

10. ProCapsule Systems

- Complete Production Line: Not only fills capsules but also offers integrated quality check systems.

- Modular Design: Easy to expand as production needs grow.

- Cost-Effective: Designed with a focus on affordability for chemist warehouses and small businesses.

YITI Capsule Filling Machine Highlights

The YITI Capsule Filling Machine is a standout model in this competitive list, especially for those focusing on size 000 capsules.

- Efficiency and Accuracy: With 100 holes, this model makes filling a large number of capsules both rapid and precise.

- Compact and Portable: Its small size (ideal for home use or boutique production) and lightweight design simplify transportation and setup.

- Easy Assembly: Designed for quick installation—the package includes all necessary tools and clear instructions.

- High Quality Material: Constructed from durable ABS, this machine withstands frequent use while ensuring that supplement integrity is maintained.

- Multifunctional: Whether you are a health enthusiast or a small business owner, it adapts well to a variety of supplement types and production volumes.

How to Optimize Your Supplement Production

Once you choose a capsule filling machine that meets your needs, consider these tips to further improve your supplement production:

- Standardize Your Process: Develop and document a standard operating procedure (SOP) for filling capsules, ensuring consistency with every batch.

- Quality Checks: Implement regular quality control checks to verify dosage accuracy and overall capsule integrity.

- Train Your Team: Provide training sessions for all operators to maximize efficiency and reduce errors.

- Stay Current: Keep abreast of new technological advancements in capsule filling to upgrade your equipment and methods as needed.

- Minimize Downtime: Schedule routine maintenance, including cleaning and component inspections, to ensure continuous operation.

Maintaining Your Capsule Filling Machine

Regular maintenance is key to ensuring your capsule filling machine maintains peak performance. Follow these guidelines:

- Cleaning: After every production run, clean the machine thoroughly to avoid residue buildup.

- Inspection: Periodically check parts for wear or damage and replace them as necessary.

- Lubrication: Ensure moving parts are properly lubricated according to manufacturer guidelines.

- Storage: Store the machine in a dry, temperature-controlled environment when not in use.

- Professional Servicing: Schedule annual professional check-ups if operating the machine in a high-volume environment.

Conclusion

Investing in an efficient capsule filling machine is essential for anyone looking to enhance the quality and consistency of their supplements, whether for personal use or in a chemist warehouse setting. From high-volume production models to compact home-use machines like the YITI Capsule Filling Machine, there is an option for every need and budget. By focusing on quality, ease of assembly, and durable construction, these 10 best capsule filling machines provide a solid foundation for reliable, consistent supplement production. Incorporating smart production tips and routine maintenance into your workflow will further ensure that you enjoy long-term success and improved cost efficiency in your supplement manufacturing process.

Summary Table

| Machine | Main Features | Ideal For |

|---|---|---|

| YITI Capsule Filling Machine | 100-hole design, compact, easy assembly, durable ABS build | Home use, small-scale production, personal supplements |

| Capsule Master 2000 | High throughput, user-friendly interface, robust construction | Medium to high-volume production |

| PharmaFill Pro | Pharmaceutical-grade precision, automated operation, compliance verified | Pharma/clinical supplement production |

| EasyFill Express | Fast cycle times, portable, cost-effective | Small businesses, hobbyists |

| AutoCap Pro | Advanced automation, adaptable, industrial strength | High-volume commercial production |

| SmartCaps E-Series | Digital control, high efficiency, real-time monitoring | Modern supplement manufacturers |

| NutriFill 500 | Ergonomic, optimized for health supplements, flexible production | Herbal and nutritional supplements |

| PrecisionCaps Elite | Superior accuracy, streamlined production line, high quality | High-end, precision-demanding production |

| CapsuleFiller X | Fully automated, versatile size range, extensive support | Large-scale operations, chemist warehouses |

| ProCapsule Systems | Modular design, integrated quality checks, cost-effective | Expanding businesses, customizable production lines |